The LED, by definition, is an opto-electronic device, which exploits the ability of some semiconductor materials to produce photons, through a phenomenon of spontaneous emission.

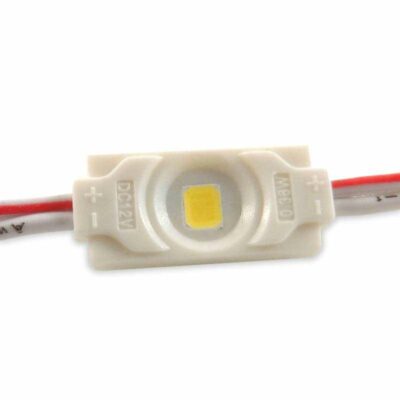

The LED module is an assembly of LED technology, consisting of an aluminum plate, on which diodes and conduction cables are applied.

These components are pressed inside a plastic shell, which gives them waterproofing and resistance.

Some LED modules are equipped with lenses, ranging from 38 to 160 degrees, which will be chosen according to the final application.

Aluminum is a conductive metal, always used in LED modules, because in addition to being resistant, it helps the chips in heat dissipation, which is essential for the longevity of any LED product.

Any LED module that is not designed with good dissipation will not be able to last over time, nor will it maintain a constant luminous flux.

Why use LED modules in signs?

The LED Module is designed exclusively for signs.

Even if its adaptability leads it to have multiple applications.

It is the best product for signs, for its robust manufacture, which allows it to be exposed to extreme weather conditions, while still guaranteeing its operation.

For example, a sign can be mounted in the city center under a balcony, then sheltered, or on a seafront establishment or in a restaurant in the mountains, but its operation must be guaranteed.

Diversity and use of the various types of LED modules

On the market we can find many types of LED modules.

They can have from 1,2,3,4, 6 up to 12 chips.

The difference is made by the application, the “wattage” (power) and the type of project we want to carry out.

The modules with 2 or 3 LEDs are usually of the same family, only their length changes, for ease of application, compared to the size of the sign.

On the other hand, when we have a module with a single chip, we have to check the size and wattage, and especially the lens, to understand how the application should be carried out.

For example, if we have a module with a chip of a wattage of more than 1.5 W and with a 38-degree lens, we can immediately understand that it is a product for double-sided signs.

The latter, unlike the others, require a higher wattage and a lens that tightens the cone of light (the chip opens its cone to 120 degrees) to overcome a certain distance and get from one side of the sign to the other.

On the other hand, a module with only one chip, a wattage below 0.5 W and without a lens, we can immediately understand that this is a small product, very useful especially for small boxed letter signs, which we usually find in the historic centers of large cities.

This is why it is a product that is very often sold with a light temperature of about 3000k (warm light).

In this regard, it is interesting to understand that in historic centers warm light is often required and used for an optimal optical effect, as well as aesthetic.

A warm light module develops exactly the same lumens as a cold light module, but this one has a brighter light, while warm light is softer and less aggressive for visual perception.

For example, in the center of Rome, where bronze-colored boxed letters are MANDATORY , warm light blends perfectly and is more elegant.

On the other hand, when using a 1.5-2 W Module with a 160-degree lens, we are certainly dealing with a product for large format signs.

On the other hand, when using a 1.5-2 W Module with a 160-degree lens, we are certainly dealing with a product for large format signs.

The 160-degree lens, which is the most widely used of the LED modules for single-sided signs.

It has a double function: in addition to widening the light cone, from 120 degrees of the standard diode up to 160 degrees, it gives us the possibility of using a reduced number of LED modules, making the light inside the sign more homogeneous.

This type of product is sold almost exclusively in cold light.

Color Temperature

The color temperature in LED modules is very important for the final effect of the project we are going to realize.

To be clear and understand where the concept of color temperature starts, let’s fix a Zero point: sunlight has a temperature of 4500 K.

From here we can talk about cold light and warm light, moving above or below this color zero.

The lower we go, the warmer the temperature, the colder we go, the colder it is.

The LED is born blue.

Then thanks to the color of the phosphorus that is applied on top (which is the more or less yellow part that you see on the chip), it is given the color temperature you prefer.

As for the LED modules, warm light is around 3000 K, natural light around 4000 K and cold light around 6500 K. Above 6500 K it is not advisable to use it, as it tends to blue and changes the final effect of our sign, whether it is white or colored.  The best-selling product is the cold light one, ideal for both direct and reflected light box letters, bins and so on.

The best-selling product is the cold light one, ideal for both direct and reflected light box letters, bins and so on.

Warm light is used as already explained above.

In addition, today the demand for natural light modules is increasing, especially because they are inside large shopping centers and airports, where natural light is already used for the lighting of shops and shops, both to keep the colors alive and to ensure a pleasant and non-tiring perception to the human eye.

Therefore, there is a tendency to use modules for signs and bulletin boards that also have natural light, so as to ensure visual homogeneity in these complexes.

LED Colors

The light of the LED modules, as we said, can have variations in white temperature, but not only.

Colored LED modules are now on the market that meet the most diverse needs: red, green, blue, yellow, orange and pink.

These are used like white light modules and can enhance the final effect of boxed letters, for example.

Today, in fact, the colored module is used on plexi of the same color, to improve its brilliance.

Many companies require this in the specifications.

In addition, RGB is a type of module that has the ability to change color and, if equipped with a control unit, can be programmed for extremely varied plays of light and color changes.

It produces different colors depending on its programming.

Feeding

The right power supply is crucial for the optimal operation and durability of the LED modules.

It must be supplied with a polarized constant current, the value of which is indicated in the data sheet.

Choosing a quality power supply , which always generates at least 15-20% more than the wattage indicated, is a simple rule, which guarantees the correct functioning of the devices.

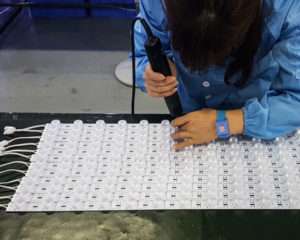

Correct assembly

To make the most of these multifaceted products, the LED Modules, it is essential to follow the rules to carry out a good assembly, which simplifies the work and maintains the result over time.

Each module is accompanied by a technical sheet that explains its characteristics and information for correct assembly.

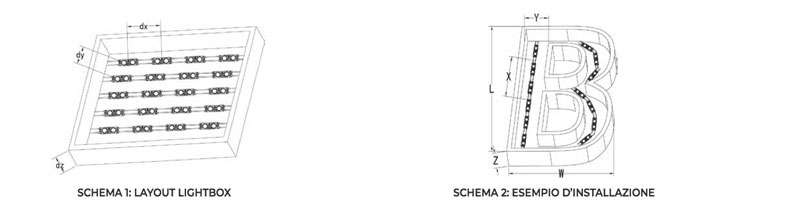

It is essential to understand that the quantity of modules to be mounted on a sign is given by its depth: the less deep it is, the more modules will have to be mounted.

And vice versa.

In fact, in the construction scheme, we will start from the thickness of the sign and from there the distance between one LED and another and between one chain and another will be indicated.

Any led module is sold in chains already separated by 20-25-30 pieces.

These chains are structured according to the current capacity that passes through them.

For this reason, the chain circuit must be closed and connected to a cable with a larger cross-section, where all the various chains are connected.

By not carrying out this procedure and connecting the chains continuously, we would let too much current pass and we could, at first, have a weakening of the LED light, and then face the interruption of light.

Signs that are difficult to maintain

When installing a sign that is difficult to maintain, for example on the wall of a building, on a terrace or in places where access is only possible with cranes or baskets, it is always advisable when mounting the LED modules to use screws in the holes they are always equipped with or a drop of silicone, To make sure that the fixing does not play tricks on us later.

Temperature fluctuations can deteriorate the double-sided adhesive, despite its quality.

In this way, the fixing will be long-lasting.

0 Comments