Many of you are wondering and asking us for clarification regarding the difference between SMD LEDs and COB LEDs.

This is why we have decided to get to the heart of the matter and we answer you with a video and an article that we hope will allay your doubts.

Let’s compare the technology of SMD LEDs and COB LEDs

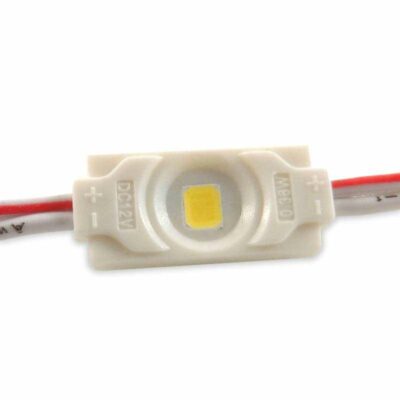

Surface Mounted Device (SMD) LEDs

This type of LED looks like a tiny plastic casing, inside which the LED chip is placed embedded with a resin casting.

The light is emitted from the upper face usually with a light emission of 120 degrees.

The prescription is variable through the use of special lenses.

The designation of the various types of SMD LEDs is given by the size of the enclosure measured in tenths of a mm (35×28, 50×50, 57×30, etc.).

The SMD LED is soldered directly onto the electronic board, while the electrical connections are lateral.

In this way, it is possible to use printed circuit boards on a reduced thickness insulator base and carry out micro-soldering with automated machinery.

COB (Chip On Board) LEDs

COB technology makes it possible to create an array of individual LED diodes assembled on a single support, which can be made of aluminum or ceramic.

This support has a surface area of a few square centimeters and can contain hundreds of LED diodes, which are subsequently incorporated with a casting of epoxy resin or silica gel.

COB technology has made small, easy-to-assemble LED chips available on the market, with high power and extremely low production costs.

These undeniable advantages have led the majority of manufacturers to use COBs on a large scale in the production of LED luminaires and lamps for lighting, even of very high power.

As for luminaires with power up to 50W and mainly for indoor use, the advantages of this innovation have been amply confirmed by the results, making it possible to create luminaires and lamps with characteristics of high efficiency, small size and great reliability, which has made it possible to replace traditional luminaires very well.

COB vs SMD for high power

As regards the use of COB technology in luminaires with higher powers, we have witnessed an extensive application by many manufacturers in the production of high power luminaires such as street lights and floodlights for area lighting through the use of bodies created for traditional lamps and adapted to house COB LEDs, or low-cost aluminum bodies in which the COB diodes are fixed directly on the structure and equipped with large lenses.

In this way, the market has been flooded with low-cost LED products but of limited reliability, as over time all these applications have shown their limits consisting in a premature degradation of the light performance of COB chips due to the limited dissipation capacity of the bodies used.

For this reason, some manufacturers have preferred to favor the production of power devices through the use of SMD diodes which generally reach powers of just over 2W but which have proved to be much more reliable in applications that require high power because in this way it is possible to distribute the heat emitted in a more balanced way.

In this way, it is possible to ensure better stability of the diodes and the luminous performance of the luminaires over time.

Emission surface and control of light distribution.

Increasingly efficient SMD chips

The race to create increasingly efficient SMD LED chips and therefore capable of reaching lumen/Watt ratios of more than 150 lm/W has made it possible to develop luminaires with ever smaller dimensions and lower energy absorption in relation to the lumens produced. SMD technology has also proven to be superior to COB technology in terms of light distribution.

Thanks to the use of optical elements in which each SMD diode can be managed individually to achieve the desired light distribution. In this way, it is possible to achieve results of absolute excellence and precision also with reference to light distribution and quality.

As for my company Easy Led Store for the Signs market, I choose exclusively SMD, as their reliability is unsurpassed to date.

COB is also gradually being used for the production of modules.

Currently in the testing phase, it does not guarantee reliability and durability.

In addition to not having a satisfactory quality / price ratio.

One of the objectives of Easy Led Store is to study.

Gather information in real time.

To evaluate, select and guarantee our customers the best of new technologies.

As long as they are actually reliable, precise and suitable for use.

We remind you that the quality of the Power Supply is the basis of the success of the use of both the SMD and the COB.

Sometimes we get stuck in the choice of the type of chip, when then, in my opinion, what really makes the difference is the quality of the power supply.

I only distribute Meanwell Power Supplies which are the TOP on the market, offering the best quality at a great price.

0 Comments